After shared about the laser, let’s talk about the communication protocol chip of Texas Instruments. Firstly, we must know that the DDC low-frequency signal is used to implement the handshake protocol. The HDMI Association stipulates that DDC specification of the HDMI product is less than 700pf, but for AOCs, the theoretical value of this set of cable is 4000pf/100m. In principle, the lower the capacitive reactance of the low-frequency signal cable, the farther the transmission distance can be, and signals will be more stable.

The existing modules have some components to reduce the capacitive reactance, and the skilled cable- producing manufacturers can reduce the capacitive reactance to 2600pf/100 meters by changing the cable-producing process, but when making longer meters, the DDC capacity resistance value will still exceed 700pf, so when we produce cable more than 60 meters, still need to use a chip module with a (TI) communication protocol. In order to ensure that the finished-product of long meters has no problem in terms of protocol communication. Smartavlink’s technicians, works from practical experience, started from the fundamental problem and specially processed on the DDC signal, to make sure I²C signal can successfully complete the Hand Shake, greatly improving the compatibility and reducing end-user’s concerns about compatibility, the figure above shows the waveform of the Smartavlink technician measuring the DDC.

Besides chip module, let’s talk about the AOC wire. At present, the quality of AOC wire has big difference, far more than standard HDMI copper wire. Take standard copper wire to make an analogy, some manufacturers take the 30AWG wire to do 3 meters of finished products that can pass EMI, bandwidth 18G, some manufacturers wire-extrusion’s the bandwidth only 13.5G, and some manufacturers wire-extrusion’s the bandwidth only 10.2G, more manufacturers draw out a wire bandwidth only 5G. Fortunately, the HDMI Association of the copper wire has detailed specifications. So you can know the quality of the cable by comparing it.

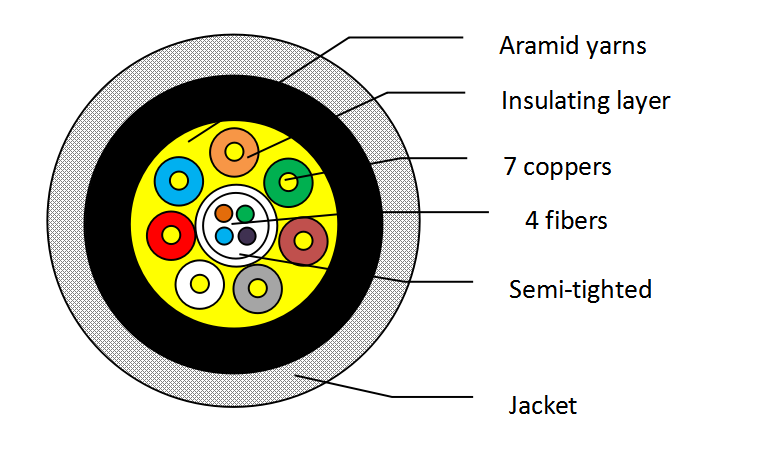

However, current AOC cable is troublesome in no standard specification to follow. At present, AOC cables generally go for 4 fibers +7 coppers wire structure. 4 fibers are used to transmit data, the 7 copper wires for communication protocols: one for power supply, one for CEC, two for Audio Return Channel (ARC), and one for DDC signals (two cores for foam plus one ground, the wire is shielded with aluminum foil). It is precisely because there is no standard to rely on, the wire materials used in the market are vary widely, and the wire performance are big difference. They are respectively OM1.5, OM2, OM2+, OM3, OM4, and the core protection is PVC and Teflon. Filling materials, such as Kevlar, Nylon, PP, and cotton. The outer jacket is made of PVC, CL2PVC, TPE, CMP, etc. Such different material options makes the cost of AOC wire very different, and the unit price span range from 1.2 RMB/meter to 15 RMB/meter. The finished wire are has big different performance as well.

Here I will talk about the wire processing of the ARC function and the capacity reactance of the DDC wire. Now, more and more users are paying attention to the ARC function of the fiber optic cable. Our conventional wire can only support ARC up to 15 meters, and many users require support to 30 meters or even 50 meters, So we have to do something special with this set of core wires, and the conductor specification is changed by foaming and aluminum foil shielding. The processing is good, and the audio sound of the finished-cable within 75 meters can be returned without any problem. When I talked about the module chip in the previous section, I mentioned the importance of the DDC wire capacitive reactance value. After hundreds of testing, we extracted the 2600pf/100m wire (the theoretical value is 4000pf/100m). Pumping AOC cables still requires a lot of technical skills. If the wire is not well drawn, the function of finished wire will be missing and the compatibility will be poor.

Finally, let’s talk about the finished product assembling of the AOC cables. The FA45, LENS, and the ceramic film are commonly used in the market as the medium for optical signal transmission. These programs have their own advantages and disadvantages. Many traditional HDMI copper cable factories are too optimistic about the market, blindly buying modules without understanding them, just simply connect it and considered it to be a qualified HDMI AOC, always achieve for lower price but sacrifice item function. Actually it is consuming the confidence of customers on AOC products. Since optical fiber HDMI used the photoelectric conversion chips, lasers optical devices etc., the problem generally takes 3 to 6 months or more to be founded out.

A quality-conscious manufacturer will partially repair the fiber core with a proper amount of UV glue after cutting the fiber, and use a BER tester to detect the bit error and bandwidth during the process. You also need to use MURIDEO to check if the data will be lost. The general small factory docked directly after using the TV test can play, it is considered that the product is no problem which will be a big hidden danger. Because too many error codes, it usually shows up after the TV has been playing for a few hours or even a dozen hours.

In summary, we have been continuously producing and improving the quality of optical fiber HDMI for 6 years. Found and solved numerous technical problems, we also feel honored that there are dozens of brands chose the fiber HDMI, DP and USB cable made by us. In the past six years, Smartavlink has developed from the original fiber optic HDMI to today’s complete and rich photoelectric conversion series product line as below:

HDMI2.0 Type A AOC

HDMI2.0 Type D AOC

HDMI2.0 Armored Type A AOC

HDMI2.0 Armored Type D AOC

USB3.0 Male to Male AOC

USB3.0 Male to Female AOC

Type C GEN2 10G AOC

USB3.0 Male to TYPE C AOC

DP1.4 to HDMI AOC

MINI DP1.4 to HDMI APC

HDMI2.1 Type A AOC

And so on……

Except for above standard products, Smartavlink also help customers design and develop special AOC solutions for special applications, including application from commercial to industrial, machine vision to medical etc.

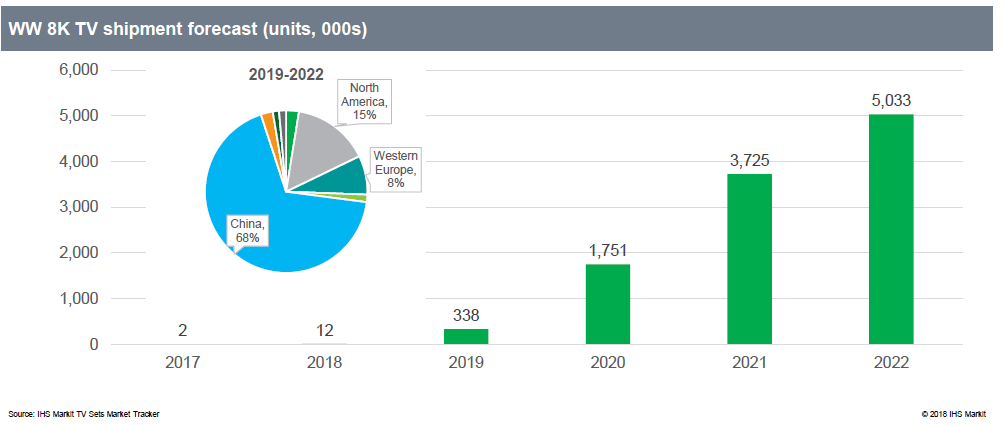

After CES show in 2019, major TV manufacturers demonstrated strong 8K application and manufacturing capabilities, and with coming of the commercial application of 5G, it accelerated the application requirements of 8K and higher bandwidth. The following picture shows FORECAST for 8K TV. We can clearly feel the huge application prospects of 8K and the growth of the market, so it also brings a lot of chance and challenge to AOC cable.

Smartavlink has been working hard at HDMI AOC field, listening to the voice of customers and quietly improving products, which has won the recognition of numerous professional users. Because such persistent, so we are professional! Thanks for the supports from our suppliers and partners all the time during these 6 years, Let Smartavlink in such a chaotic market to focus on quality and continuous development, Let’s work together and walk farther in the future.

Smartavlink team has confidence and capability of leveraging the technical advantages and R&D capabilities in 8K and higher applications, and using the concept of photoelectric converting technology to help more customers solve more application difficulties in the future.