Recently, there are various price for fiber optic HDMI cables on the market. Take 10 meters for example, unit price is lower at $10.00/pc and higher at $100.00/pc or more. Some manufacturers say that HDMI fiber optic cable just a high-frequency cable which has no technical content, and it can be guaranteed for life. This made me thoroughly understand the phrase ‘Ignorance is fearless’! Smartavlink has been working in AOC for more than 6 years. Here we take a chance to introduce why there are so many different offer on AOC. For end-buyers, you will probably know how to select a good quality AOC after reading.

Smartavlink started AOC with TOSA & ROSA from the earliest HDMI V1.3, and has been modularized by today’s COB process. During these years, we have experienced countless failures and testing. Main factor like “Compatibility Issues”, “I²C communication”, “Reliability & Stability”, has been continue researched on production line to make sure our AOC are better compatible with a wide range of devices on the market. In my personal understanding of HDMI AOC, there are four aspects need pay attention to:

‘AOC product generation background’

‘AOC module design’

‘AOC cable process requirements’

‘AOC finished-product quality control’

We will follow each one to talk more and also would love to hear any difference voice around this topic. Please feel free to write to info@smartavlink.com.

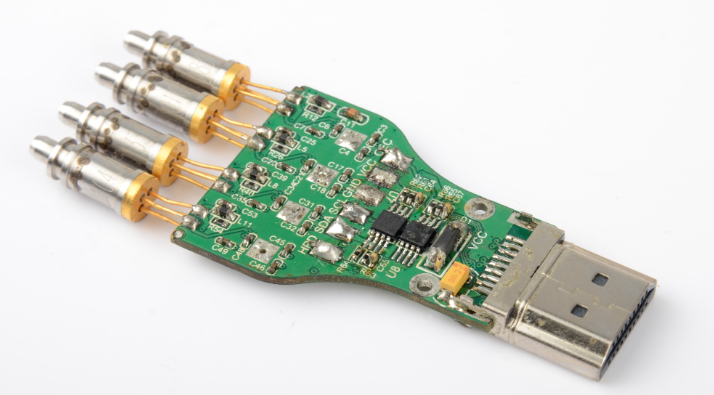

The following picture shows the first-generation HDMI1.3 AOC developed by Smartavlink in 2013, using the design ideas of TOSA & ROSA.

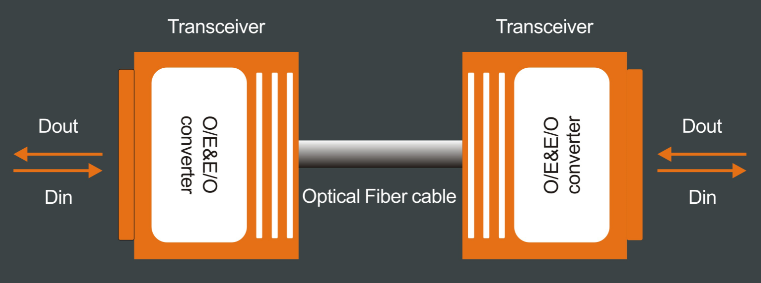

AOC full name is “Active Optical Cable”, The design idea is to convert the high-speed signal part of products such as HDMI/DP/USB into optical signal, as traditional copper cable has limited on longer distance transmission based on its natural physical properties. HDMI/DP/USB AOC all take fiber as special medium, in theory, the bandwidth can be increased with no limitation, and there is no signal attenuation over long distances. The market always show big potential needs of long-distance transmission applications, It brings more possibility of application such as HDMI/DP/USB etc.

Nowadays, the application of high-definition video is becoming more and more popular, from personal mobile phones to commercial Screens, industrial medical, etc., more and more scenarios provided AOC application requirements, and AOC will bring more application requirements with the arrival of 5G. Based on this background, Smartavlink team has been consist engaged in the development, design and manufacturing of HDMI/DP USB fiber optic cable etc since 2013, no any copper cable. It’s the only product we’ve being doing for 6 years. I believe that as the market division of labor becomes more and more detailed, focus and professional will allow us live longer and run farther.

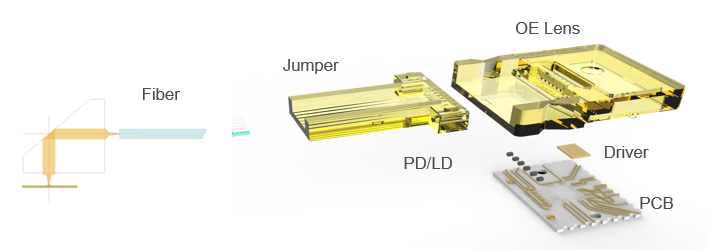

First, let’s talk about the module. The module is mainly composed of the main chip + laser. Some modules are composed of main chip + laser + DDC buffer chip. At present, the most used in the market is the Germany brand main chip (Silicon line) + Phillips matrix laser (VCSEL), and some modules are also added Texas Instruments (TI) DDC BUFFER CHIP, used to for making long cables. The main feature of Silicon’s chip is: stable performance, low power consumption, with early develop and enter in the market, it is the mainstream driver chip right now. Their power consumption of TX is generally around 200mW, and RX only about 160mW, so almost all playback and display devices can support its work.

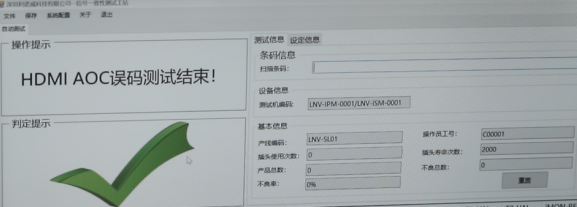

But just because such high achieve on low-power consumption, it turns out its light eye and the electric eye are not large enough, end up with too many error codes in the finished-product. When used on high-end devices (such as Apple Box and SONY TV combination), there will be flash screen and noise for individual products. So Smartavlink developed a fully automatic error code tester for this problem to ensure that each cable can meet the application needs of top professional customers, thus reducing the risk factor of splash screen and noise (check below pictures).

Some module manufacturers chose other chips, since these chips are generally used in optical communication/ DATA CENTER, the photoelectric eye effect of these chips is better than Silicon-line, but the biggest problem is big power consumption. Their TX power consumption is good, generally around 200mW, but RX power consumption often exceed 300mW. Current all chip modules need get power from both side devices. Excessive RX power consumption means you have to get more power from the display side, which may blacken the display device and makes the chip’s compatibility all not good. Also, some of devices may unable to supply such large amount of power, then it will need external power supply, it will be inconvenient for end user using.

At present, there are many module factories in this market, mainly come from United States, South Korea, and mainland China, and including Taiwan area, but overall, there is no 100% perfect so far, because HDMI AOC is a non-standard product on the market. All chip and module manufacturers are still working hard!

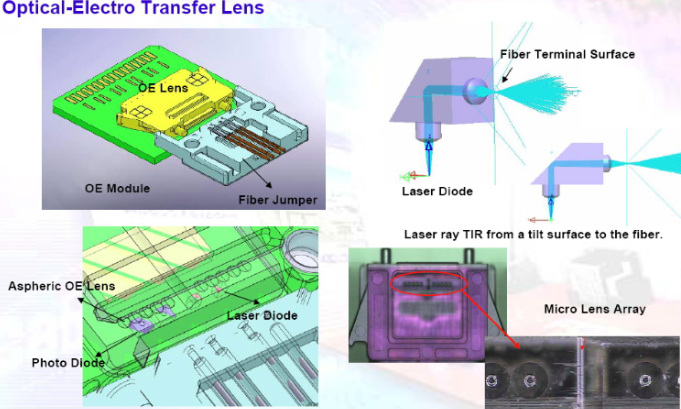

Besides main chip, laser is also very important. Most modules use Phillips matrix laser (VCSEL), and some modules use II VI, some of higher end-users use Finisar laser. Many users knowing the Silicon-Line driver chip, but don’t quite understand what is VCSEL laser. The figure below shows the working principle of VCSEL used on AOC:

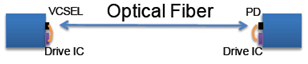

Because all AOCs need covert it’s electric signal to optical signal first, then pass optical signal from Source Side to the Display Side. Then Display side covert its optical signal into an electric signal such as HDMI/DP/USB. This will be the complete link for all signal transfer, see following working principle.

Due to the limitation of design and manufacturing process, the lasers from different manufacturers have different intensity of optical power, and the life of the laser is also inconsistent, which will directly lead to the emergence of HDMI AOC cable after being embedded in the pipeline. It may turns like Splash screens, black screens, and even direct failures after one month or two months. The four-way lasers may extinguished one first and it is a hidden dangers.

In response to this problem, Smartavlink technical team has developed a set of equipment to monitor the optical power consumption of 4-way lasers to ensure that all products have reliable optical paths, and reduce the degradation caused by the VCSEL laser. Following picture is show Smartavlink’s private designed equipment to testing 4 fiber channel signal loss.

After tested the Optical signal loss, Smartavlink also establish a QR code traceability system, so that each product has a unique ID card, can be traced back more than 10 years from production date, to help customers bring more confident on choose Smartavlink’s products, and distinguishing from those low-priced products. We believe that it is not just a cable, it is a electronic & fiber optical device, it has more requirement than just a cable.